YAOJIA folder gluer can process straight line boxes, crash lock bottom boxes, double wall boxes and 4/6 corner boxes solid board up to 800 gsm and micro-fluted box flute E and flute F.

YAOJIA folder gluer can process straight line boxes, crash lock bottom boxes, double wall boxes and 4/6 corner boxes solid board up to 800 gsm and micro-fluted box flute E and flute F.

|

Model |

Pace-Setter YJB-1100 |

|

Paper Material |

Paperboard 200-800g/m², E and F flute corrugated paper |

|

Min size(W×L) |

76×60mm |

|

Max size(W×L) |

1050×800mm |

|

Max Speed |

400m/min |

|

Feeding Way |

Automatically and continuously feeding, Servo motor controlled |

|

Way Of Folding In Reverse |

First crease line pre-folder up to 180º. Third crease line pre-folder up to 135º |

|

Glue Type |

Water base glue |

|

Power Supply |

3P 380V 50HZ |

|

Main Motor Power |

11KW |

|

Total Power |

23KW |

|

Weight |

7t |

|

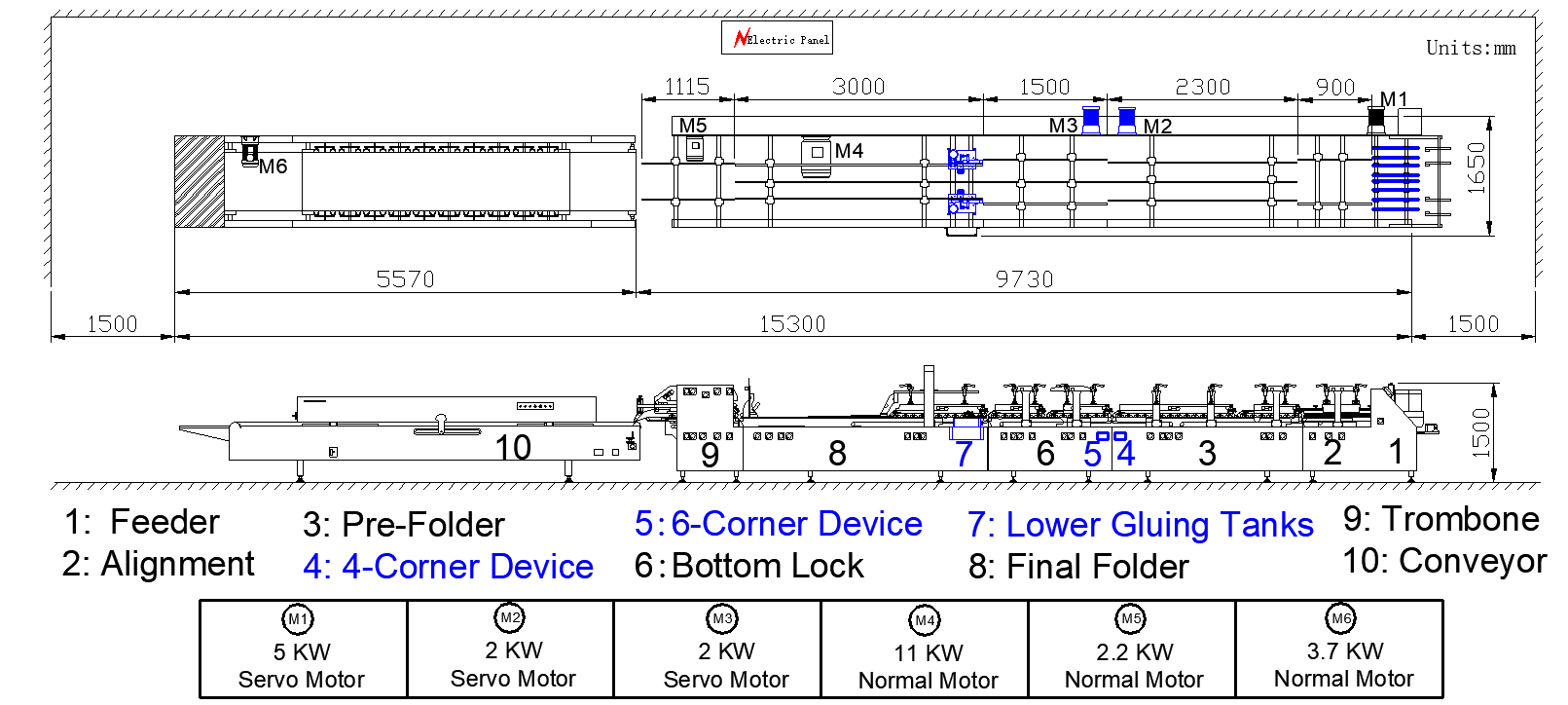

Overall Dimension |

15.3×1.65×1.8m |

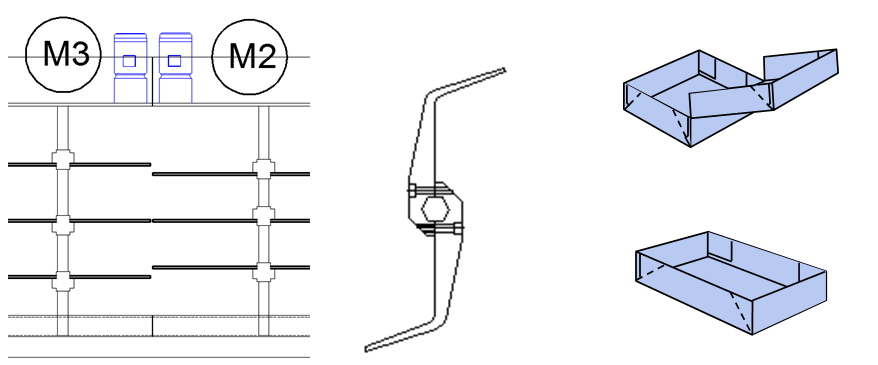

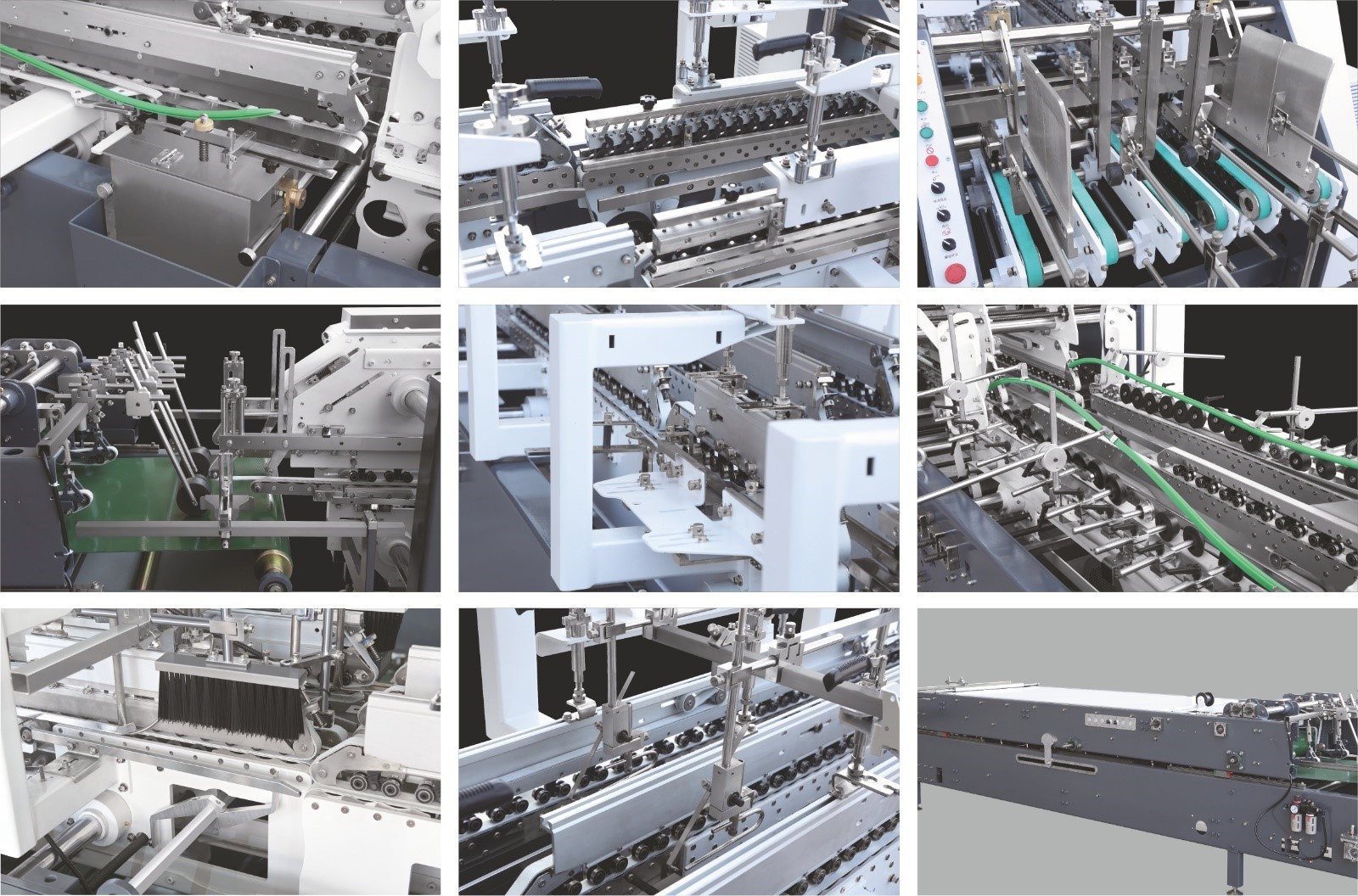

Feeder

Fully Automatic Feeder With Servo Motor 5kw

8 pcs 30mm Friction Belts Soft Rubber Compound (optional extra 4 vacuum belts)

4 Back Carton Supports

3 Front paper supports (Quick adjustment for thickness of substrate)

2 Paper Side Guides

Vibrator

Full Colour Video Monitor (Supervise view final product at the end of the Machine)

Aliening unit

2 Bottom Transport Carriages (fitted with 34mm wide Belts)

1 left Hand Side Squaring Guide

1 Right Hand Side Squaring Guide

4 Top paper support guides

Adjustable top Carriages fitted with independent lever system which can be independently applied giving the desired pressure required for the alignment of Substrate carton blank

Electronic movements of carriages in and out of working position (Via remote control)

Pre Fold Unit

1st and 3rd crease

Bottom left had side carriage 43 millimeter wide belt

3 Bottom Carriages

3 Top carriages

Electronic movements of carriages

Crash bottom lock unit

3 Bottom Transport carriages

3 Top Transport carriages

4 Sets of crash lock hooks

3 Sets of diagonal folding shoes 2 Unit per Set

Bottom chromed support bars

Electronic movements of carriages in and out of working position (Via remote control)

4 And 6 Corner (Optional)

2 Servo Drive Motors 2kw Each

3 Folding Hooks 4 Corners

3 Folding Hooks 6 Corners

6 Corner Box Lid Can Be Folded from the Left or Right hand side Of Machine

Moveable Touch screen Commander Module (For programing Measurement’s: Speed and position and Electronic angel of the folding Hooks)

F inal Folding Unit

inal Folding Unit

Folding 2 and 4 crease

Equipped with 2 glue tanks 1 Left 1 Right with 5 M/m disc

Guide rollers Left and right

Adjustable speed control of belts left and right

Movement of carriages electronic (via remote control)

Removable Center top and bottom carriages (For production of small size boxes)

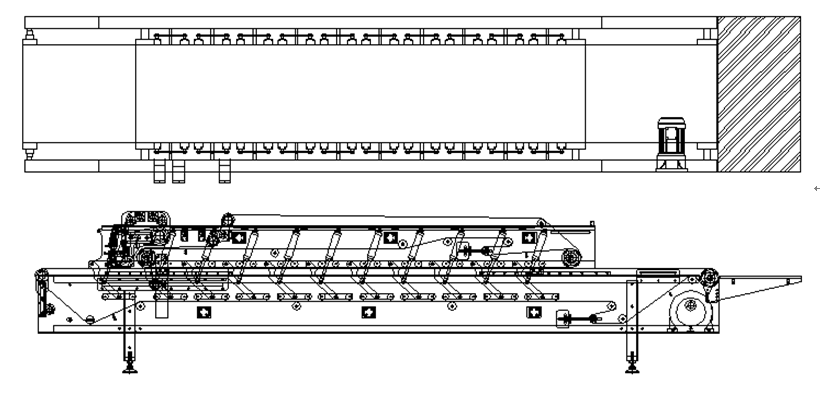

Trombone unit

Double Trombone (Telescopic)

Servo Motor driven 4 KW

Motorized variable speed control of Belt Speed for smooth delivery

Moveable Touch screen Commander Module (For Programming Measurement’s,Substratelength,Distance between substrate carton blank, speed of trombone unit, Batch counter Pneumatic kicker for batch count quantity )

Pressing unit

Pressing unit

1 Drive Motor (Standard 3.7 KW)

Front and Backward position

Pneumatic pressing (Adjustable via Pneumatic Regulator valves)

Pneumatic Front Stops (Squaring Device)

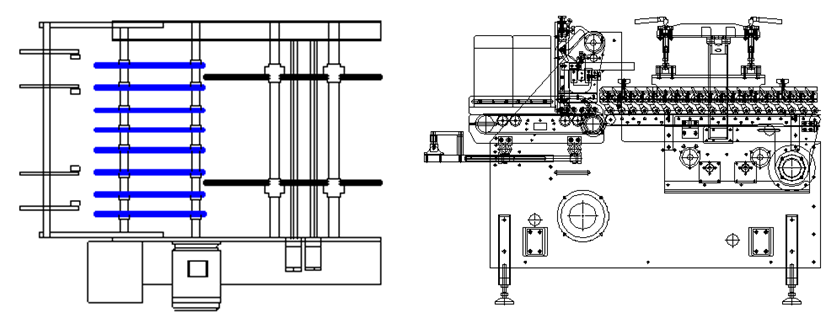

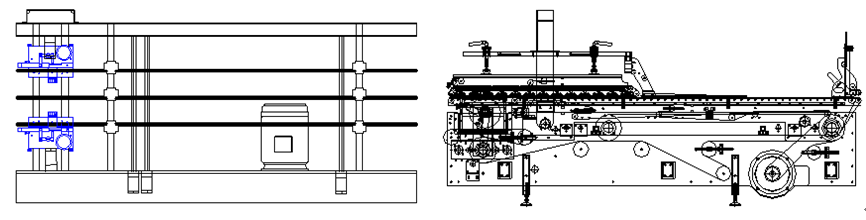

YAOJIA folder gluer machine can process straight line boxes, crash lock bottom boxes, double wall boxes and 4/6 corner boxes solid board up to 800 gsm and micro-fluted box flute E and flute F

YJS-900FL, It is new design with Hookless Module.

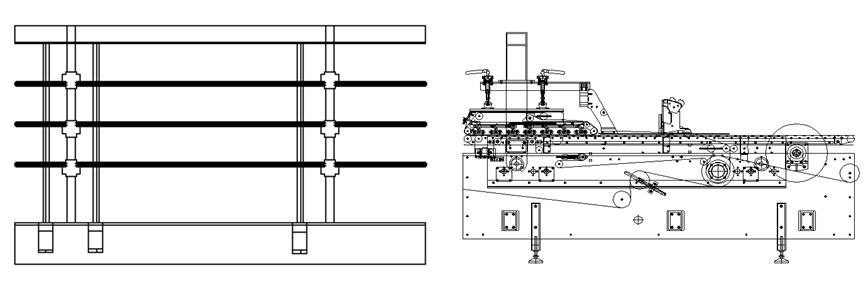

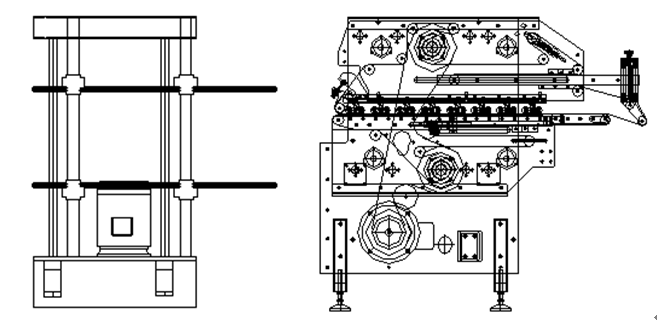

YAOJIA folder gluer machine can process straight line boxes, crash lock bottom boxes, double wall boxes and 4/6 corner boxes solid board up to 800 gsm and micro-fluted box flute E and flute F

YJS-1200FL, It is new design with Hookless Module.

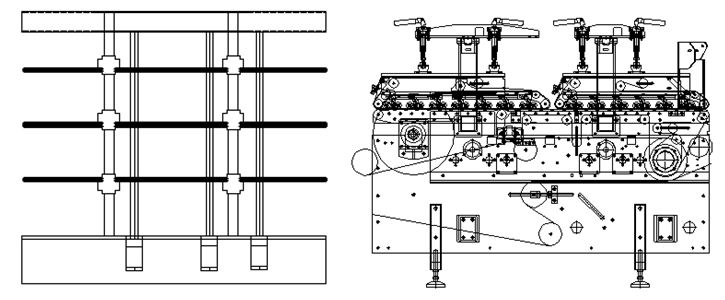

YAOJIA folder gluer can process straight line boxes, crash lock bottom boxes, double wall boxes and 4/6 corner boxes solid board up to 800 gsm and micro-fluted box flute E and flute F